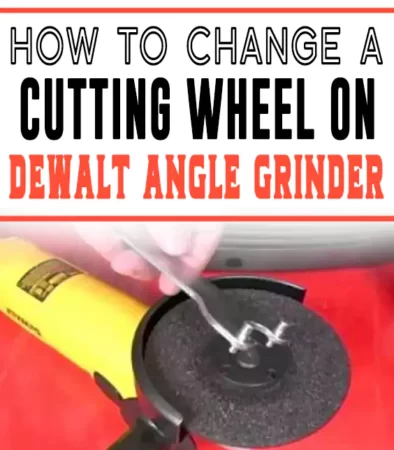

With these instructions, you’ll learn how to replace a cutting wheel on a DeWalt angle grinder without running into glazing, loading, or flange issues.

DeWalt angle grinders are exceptional machines with a cutting wheel perfect for materials like stone, concrete, marble, wood, and metal. We reviewed 6-inch angle grinders and recommend the DeWalt as a durable and versatile option.

Despite the tool’s reliability, lightweight, and compact design, it is suitable for smoothening and grinding hard surfaces.

Only 4 Steps Needed to Change the Cutting Wheel

This step-by-step guide will help you understand the cutting wheel replacement without running into loading, flange, or spindle lock issues.

Step 1: Unplug the Grinder from the Power Source

Safety is an integral part of the machine’s operation. You need to put items like goggles, leather gloves, earplugs, and necessary protective items in place starting up the tool.

Before you consider changing or replacing cutting wheels in the machine, your first task is disconnecting the tool from power.

If you’re using a corded angle grinder, unplug from the power source to prevent unexpected accidents.

But if you have a cordless machine, the handling and mode of operations are different. First, remove the battery. When you remove the battery from the device, it becomes lighter and easier to replace a cutting wheel.

Tap and hold the spindle lock on the machine’s stem. You will find this lock between the wheel protector and the body. It’s time to swing your hands into action.

Use your hand to rotate the wheel until it falls into position.

Step 2: Unscrew Old Disc

After getting your protective gear in place and unplugging the machine from the power source, it’s time to remove your old angle grinder disc from the machine.

When you purchase a new grinder, it usually comes with two wrenches to serve various purposes.

The first one looks like a regular wrench, while the other looks similar to a long fork. Both wrenches are ideal tools for removing cutting wheels from the machine.

If you’re wondering how to use a wrench to remove cutting wheels from DeWalt angle grinders, firstly mark out the hole between the disk and motor.

After marking the holes, it’s time to insert the prongs before using the wrench spanner to bolt the bottom of the cutting wheel. Many people make a mistake here by fixing the blade the wrong way.

If your disc arrow faces one direction, the pronged spanner should face the opposite. It will be best to turn the pronged spanner in the other direction of the blade arrow.

Remember that you need to hold the nut in place. Secure the wheel and ensure it spins counter-clockwise with the wrench before moving to the next step.

If the original wrench is missing, consider using a regular one.

Step 3: Remove the Disc

Now that you can loosen necessary bolts, it’s time to focus on removing the old cutting wheel before replacing it with a new one.

If you want to drive the bolt efficiently, make sure the vice grip holds the disk bolt tightly before starting operations.

The vice grip keeps the cutting wheel in position and prevents unnecessary spinning that may derail your project or cause injuries.

Use the tool to unscrew the bolts between the disc and motor before turning it in the opposite direction.

The process should loosen the old disk, and you can begin the extraction process. If the disc fails to loosen, get your hammer.

Forcefully use it to turn the screwdriver before removing the backer plate and old wheel from the machine’s stem.

Step 4: Insert the Cutting Wheel

After completing the first three steps, your old disc should be easy to remove. Remove the cutting wheel with your hands and clean the surface with a rag.

It is advisable to clean the surface to remove debris or dirt that can cause unexpected damage.

Now that you can remove the old disc, it’s time to replace it with a new cutting wheel. Place the wheel into the machine’s drive bolt and ensure you put it correctly for optimal performance.

It would be best if you used the right disc for your DeWalt machine. It should be sized appropriately for the diameter of your angle grinder.

Use your hand to tighten the disc in the opposite direction, similarly to the old one.

Let the hump rest on the wheel’s top inside the backing plate. Bolt the nuts to the stem until it starts to spin. Ensure you hold the spindle lock while using the wrench to bolt the nuts.

Types of Angle Grinder Discs

- Straight grinding wheels: These essential wheels are ideal for workshop projects. If your project involves sharpening tools like lawnmower blades or chisels, consider investing in this wheel for its unique quality.

- Large diameter wheels: These wheels are usually larger than others. If you want to grind asphalt, this tool will impress you. Just make sure your angle grinder can handle the larger diameter.

- Grinding cup wheel: If you’re grinding concrete or stone, this is your go-to tool. Although this tool has a small grit, it comes with cup wheels ideal for delicate projects like removing adhesive or paints.

- Grinding dish wheel: This wheel has similar looks to the cup model but comes with a thin surface edge. The dish wheel has a narrow shape making it perfect for tight areas. It also functions exceptionally for blending.

- Segmented wheels: These tools come in different styles and with segmented abrasive sections applied to the wheel. Each style has its unique mode of operation and can work on materials without damaging the surface.

- Cutting face wheel: You can cut through various materials with this wheel. It has a narrow width, making it ideal for large cuts. If you want wheels that can cut tile with precision, consider investing in this tool.

Summary

Now you understand how to change a cutting wheel on DeWalt angle grinder. Since the disc usage involves cutting, blending, and grinding concrete surfaces and other materials, select the right cutting wheel for your project. Some wheels are ideal for cutting, while others are good for sharpening.

Recent Posts

Many DIY lovers and engineers want to build something cool in their garages. What's cooler than a kit airplane? In this setup, the builder receives parts and puts them together in their own space....

Diamond blades have various uses, from cutting tiles and glass to cutting gems and semiconductor materials. If you’re planning to start a renovation or building project, you’ll need a diamond...