No matter why you need to shorten a bolt, cutting off a bolt head using an angle grinder is a great skill to have.

Can You Cut a Metal Bolt Using Angle Grinder?

You will need an angle grinder with a sturdy disc such as a diamond disc. This tool will be comfortable to grip and have a powerful motor to cut bolts with ease. Be sure to use a cutting disc, not a grinder disc, which is thicker and used for other functions.

How to Cut off a Bolt Head Using Angle Grinder

These are the tools you will need for cutting bolts with angle grinder:

- Bolt: It may be lose or attached to something

- Marker: You may use a sharpie pen or marker

- Ruler: Using a tape measure is appropriate as well

- Nuts: Two will be necessary

- Abrasive Pad: To smooth edges after cut

- Wrench: To screw the nuts

- Bench Vise: To hold the bolt in place

- Safety Glasses: To protect your eyes

- Ear Protection: To protect your hearing

- Angle Grinder: Cuts the metal bolt

- Cutting Disk: Attaches to the grinder

Step 1: Mark the Cutting Line

Using a sharpie marker, draw a line on the bolt where you plan to cut. Measure the bolt using a ruler or measuring tape to ensure precision. The finished length has to match the length you need.

Step 2: Place Two Nuts on the Bolt

Next, you will screw two nuts until reaching the base of the bolt. The nuts must be close to each other and tightened.

This step is necessary to make the bolt easy to clamp to the vise. The nuts will also assist you in lining the threads as you cut the bolt to the desired size.

If you don’t put on the nuts first, you will have a difficult time putting on the nuts after you cut the bolt because the threads can get damaged.

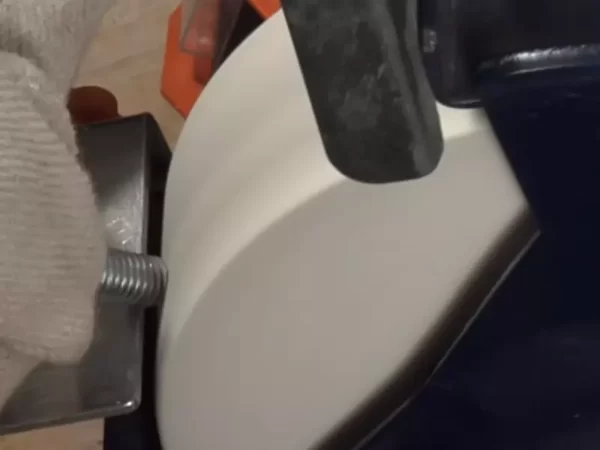

Step 3: Clamp Bolt on Vise

Once you finish screwing on the nuts, the next step is to clamp the bolt securely on the vise.

The position of the bolt must be accessible and allow you to comfortably use the grinder to cut. The bolt must be tightly secured to avoid it moving once it touches the grinder.

Step 4: Use Protective Safety Gear

Before turning on the grinder, it is important you wear safety glasses to protect your eyes.

Since the grinder can be very loud, it is also advised to use hearing protection. You may be tempted to skip this step, but you must protect at least your eyes.

There have been terrible accidents that have sent people to the emergency room because they failed to use protective gear. It is better to be safe than sorry as the saying goes.

Step 5: Cut the Bolt using Angle Grinder

Once you attach your angle grinder to the appropriate cutting blade, slowly and carefully turn it on. You will cut through the bolt smoothly, without much pressure or force. The last thing you want is to use forceful movements with any sharp tool.

For the best results, follow the cut line you have marked by using a flat angle while avoiding altering the threads. You are now ready to cut through the bolt in a smooth and gentle motion. Again, do not apply any force or pressure.

The whole cutting procedure is very quick, perhaps you will complete it in less than one minute. Take your time and pay attention to every movement you make.

Hold the handle firmly to prevent the grinder from slipping out of your hands and accidentally injuring you.

Also, when you make the cut, be sure to turn the blade away from your body making sure that there’s nothing in front of it that can be harmed.

When you complete the cut, unplug and turn off the grinder immediately, then store it in a safe place.

Do not grab the bolt after you cut it because it may become hot to the touch. Instead, wait until it cools off and handle it with care to prevent any metal dust from dispersing.

Step 6: Deburr the Newly Cut Bolt

To deburr is to smooth out the edges that the bolt may have after cutting it. With an abrasive pad, polish the bolt until you know there are no more sharp edges that may scratch your skin.

Step 7: Re-Form the Thread

To make the bolt usable, it is now time to re-form the thread. First, you will unscrew the two nuts you placed on the bolt before cutting it. Unscrew the nuts towards the top of the thread where you notice resistance.

You will need to use a wrench to make it easy to take the nuts off the bolt. Once the thread is properly re-formed, you will be able to use the bolt as needed.

Can You Cut a Metal Bolt and Still Use it?

Yes, you will be able to use the cut bolt as long as you screw on the nuts on the bolt before cutting it as instructed in step two above.

After shortening the bolt, be sure to file away any excess metal off the rim of the cut. If you know how to cut bolts properly, they will be functional.

Will a Hacksaw Cut Through a Bolt?

Yes, besides the angle grinder you may use a hacksaw. A hacksaw blade cuts various types of materials including plastic and wood. It is an excellent tool for cutting through metal.

How Do You Cut a Bolt Without Damaging Threads?

By attaching the nuts, you will have the option to mount the bolt square on top of a chop saw, which prevents thread damage. Remember to use the abrasive pad to file away excess metals to make the thread usable.

How Do You Cut Bolts That Are Too Long?

The same method applies for cutting bolts that are too long compared to the ones that are shorter in length.

For larger bolts, some people find using a hacksaw more effective than an angle grinder. Find nuts that match the size of the larger bolt to ensure you keep the thread intact.

Does Cutting a Bolt Weaken it?

No, as long as the bolt does not become overheated. You may dip the bolt in motor oil while they are still hot to prevent the material from becoming weak.

The oil keeps the temper in the metal after it has been heated. To prevent the cut end from rusting, paint over the exposed metal.

There you have it, an easy and safe way to cut through a metal bolt. By following these simple steps, you will be able to shorten bolts to the appropriate size for any project.

Remember to use the cutting disc on your grinder, which is thinner than the grinder disc.

Utilize a sturdy vice grip to hold the metal bolt firmly in place as you make the cut. Always screw on two nuts on the bolt before cutting it to protect the functionality of the thread.

Once you perform this procedure a couple of times, you will be able to do it more efficiently. Work slowly with precision and patience, take your time to avoid any mistakes or serious accidents.

Lastly, cutting off a bolt head using angle grinder in a safe manner is a priority.

Recent Posts

Many DIY lovers and engineers want to build something cool in their garages. What's cooler than a kit airplane? In this setup, the builder receives parts and puts them together in their own space....

Diamond blades have various uses, from cutting tiles and glass to cutting gems and semiconductor materials. If you’re planning to start a renovation or building project, you’ll need a diamond...